Autoclavable soft actuators made of medical silicone elastomer for adapted stimulation of cell growth

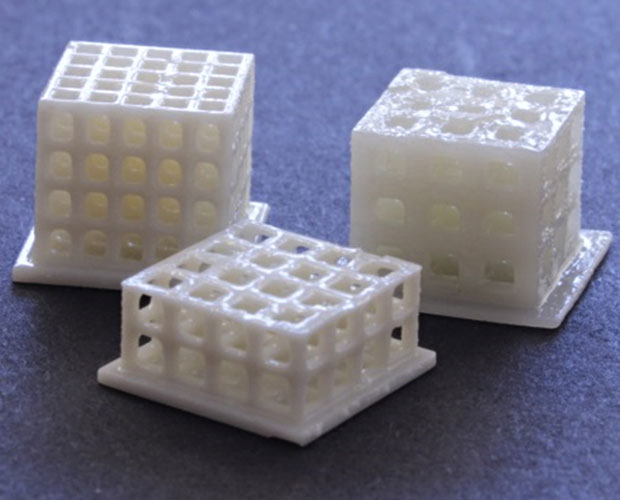

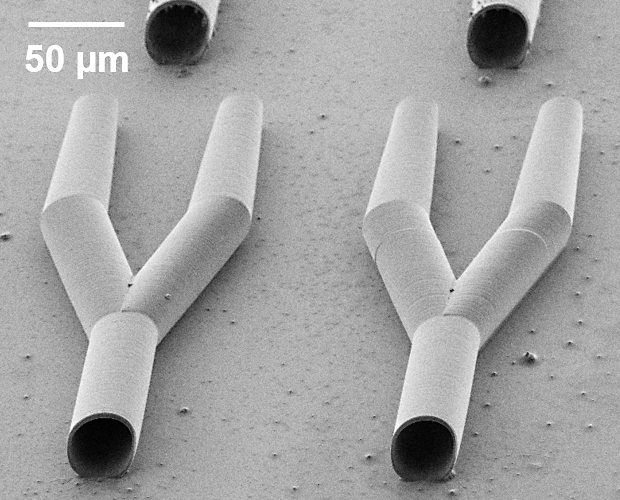

CeSMA develops soft actuators made of medical grade silicone elastomer that are autoclavable and can therefore come into direct contact with biological cells.

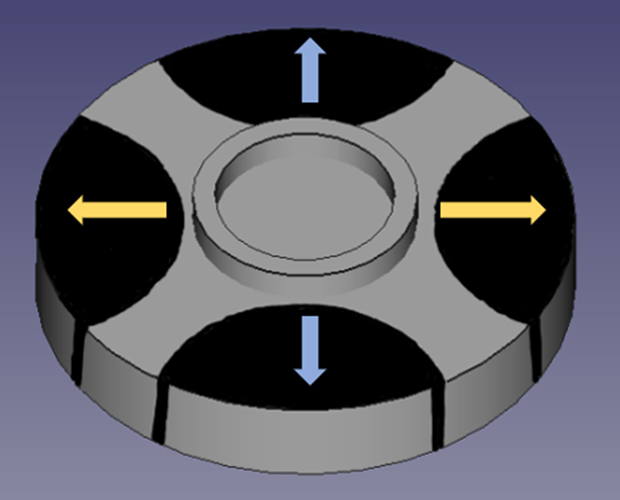

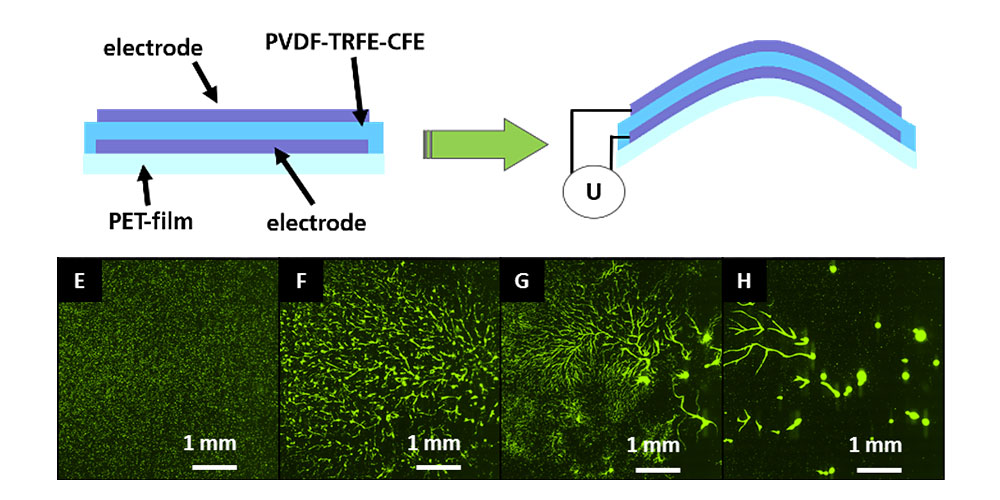

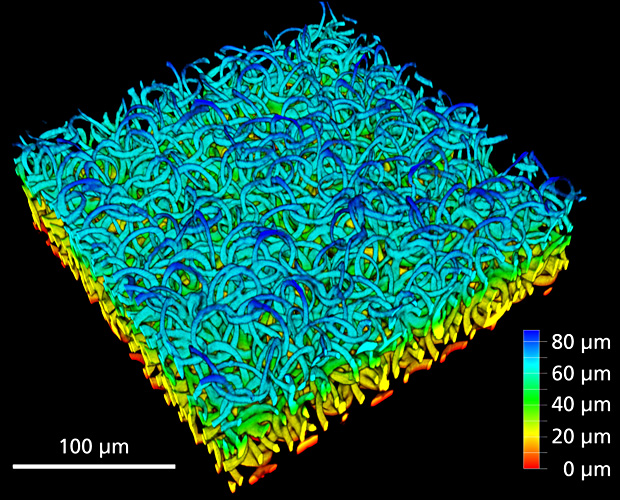

The aim is to control and promote both cell growth and the direction of growth through biaxial, mechanical stimulation. By using electrically conductive silicone, the cells can be electrically stimulated at the same time, allowing them to differentiate as i.e. muscle cells. At moderate frequencies of around 1 Hz, the actuators can perform an actuation of up to 10 %. Cell adhesion is adjusted by surface pretreatment and structuring of the silicone film.