The management of risks is becoming increasingly important to ensure human health, but also the mechanical stability and functionality of objects and machines. CeSMA has developed components for various fields of applications that contribute to increase safety using tailor-made sensors.

Technical monitoring

Process and structural health monitoring for special applications

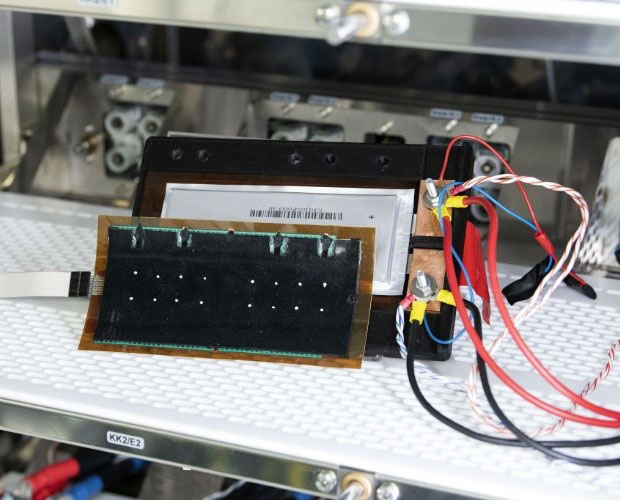

Health monitoring of battery cells

Monitoring the expansion of battery cells by using dielectric elastomer sensors that are clamped in the battery module.

CeSMA is developing sensor solutions that can measure the expansion of battery cells with spatial resolution in order to monitor the health and safety state of battery cells.

Large-scale structural health monitoring with ultrasound

Transducer element in glass solder on steel tube.

Long-term stable ultrasonic sensors that use ultrasonic pulses to monitor safety-relevant structures can detect even small cracks with high precision in vehicles, airplanes and wind turbines.

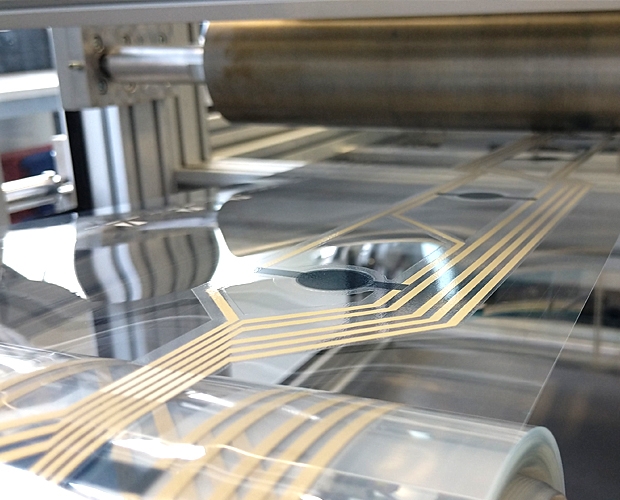

Process monitoring

Piezoelectric pressure sensors printed on roll to roll for spatially resolved monitoring of a roll gap.

Printed pressure sensors using a roll-to-roll process can measure pressure over a length of several meters, even in difficult process environments.

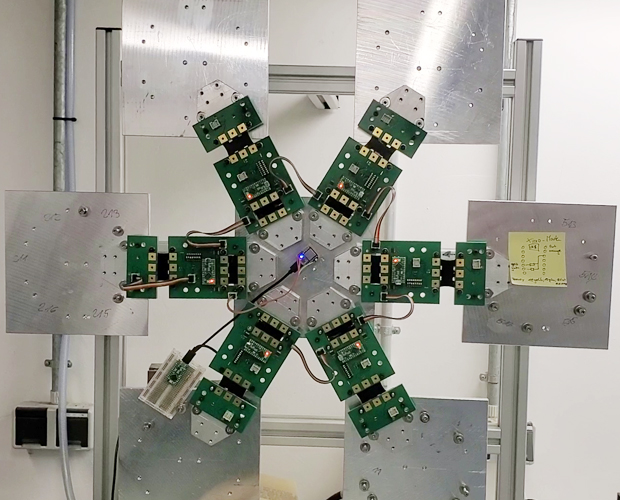

Structural health monitoring - crack detection

Star-shaped arranged strain sensors for detecting smallest strains in three directions.

Using dielectric elastomer strain sensors from CeSMA, very small strains (µm) in various surface directions can be detected during crack formation.