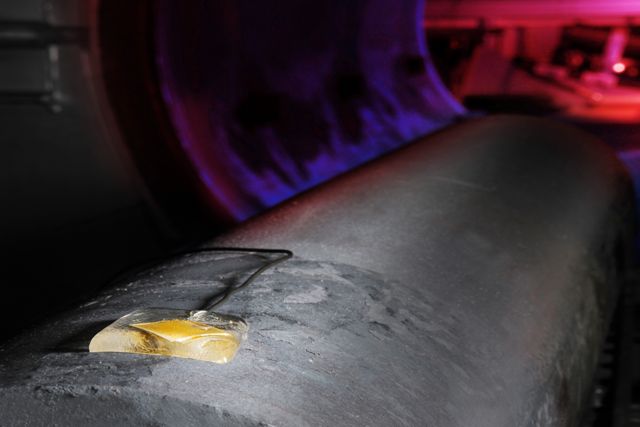

Piezoelectric single crystals (e. g. Langasite, Langatate), embedded in special glass solders and contacted with precious metal leads, can continuously record vibrations or ultrasonic emissions on hot (up to 600°C) components or generate ultrasound. Changes in the sound pattern allow conclusions to be drawn about the structural integrity of the component. The application of glass solders makes it possible to adapt these transducers to component curvatures and specimen materials in a corrosion-resistant manner and thus to implement a continuous structure monitoring system.

Non-contact and extremely fast measurements of high gas temperatures and their temperature change in the millisecond range can be carried out with high temperature ultrasonic transducers. The temperature dependence of the sound velocity is used to record even very fast temperature changes by means of transit time measurements.

Competence:

- Assembly and joining technology using glass solders for the application of high-temperature ultrasonic transducers

- Data evaluation and interpretation of ultrasonic signals

Offer:

- Adaptation of ultrasonic transducers to (corrosive) components for continuous measurement

- Component equipment with transducers and signal interpretation also on operating plants